- Machine Vision

- Vision Sensor

- 2D Machine Vision System

- Vision Tools

- 3D Machine Vision System

- OEM Products

- Barcode Reader

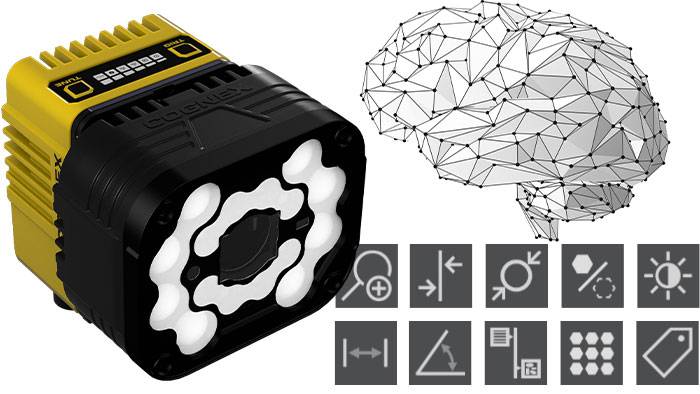

All-in-one vision system solves all your vision needs

High speed, high resolution, high flexibility. The In-Sight 3800 has it all.

This advanced vision system provides a powerful, yet easy-to-use, solution for automated inspections. Embedded with a full set of robust rule-based tools and innovative edge learning technology, In-Sight 3800 solves a wide range of manufacturing applications, from defect detection and assembly verification to character reading and more. It also enables you to:

- Run more inspections in less time – Maximize throughput with high-speed processing and quick setup

- Improve the accuracy of your results – Generate high-contrast, high-resolution images that detect even the most subtle defects

- Seamlessly scale your solution – Solve jobs, from easy to complex, using a common software platform

Accommodate the fastest line speeds and optimize throughput

Automate in minutes with edge learning technology

Deploy proven rule-based tools for more advanced jobs

In addition to edge learning tools, In-Sight 3800 offers a comprehensive set of rule-based tools. The tools can be used individually or combined, giving users the ability to leverage the best of traditional, rule-based vision and AI technology. The rule-based tool set allows you to measure distance and blobs, count pixels and patterns, read codes, guide robots, perform math and logic, and more.

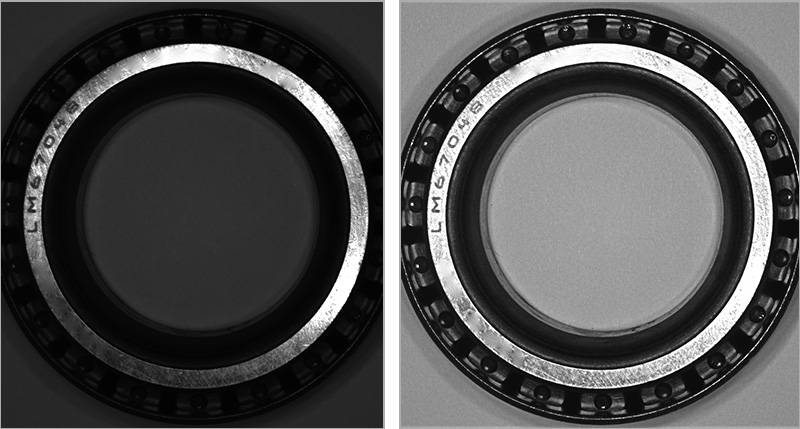

Meet higher quality standards with powerful image formation

Push the boundaries of HDR

Address a range of applications – from simple to complex – with flexible development options

Address a range of applications – from simple to complex – with flexible development options

The detect tool embedded within the In-Sight D900 is ideal for finding anomalies on complex parts and surfaces, even in situations where defects can be unpredictable in their appearance.

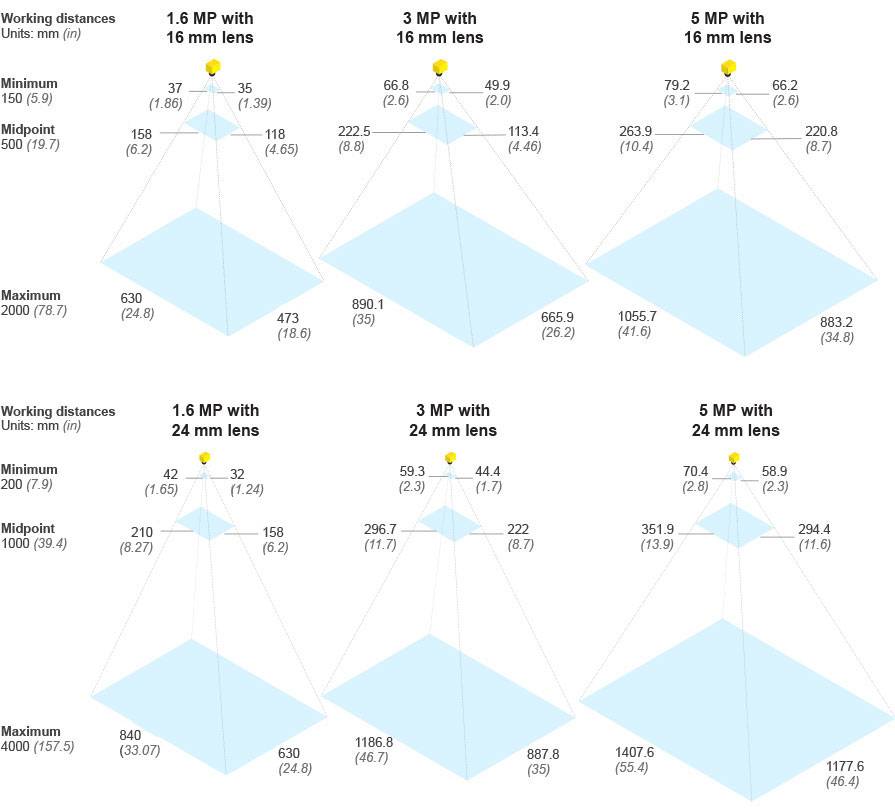

Adapt your solution as your needs evolve with scalable hardware

Adapt your solution as your needs evolve with scalable hardware

The detect tool embedded within the In-Sight D900 is ideal for finding anomalies on complex parts and surfaces, even in situations where defects can be unpredictable in their appearance.

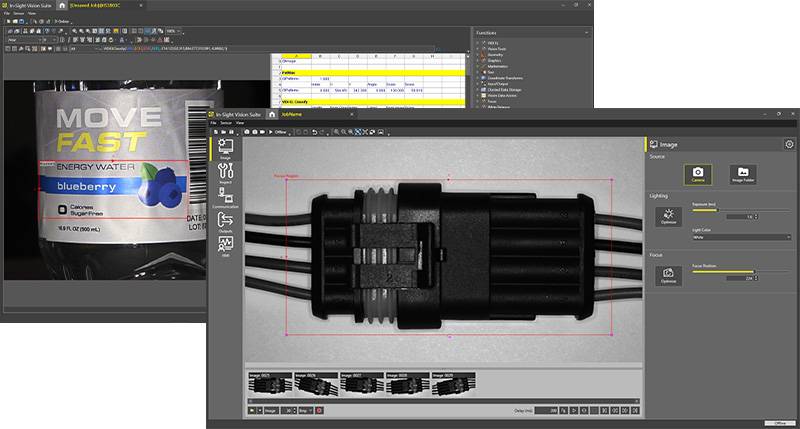

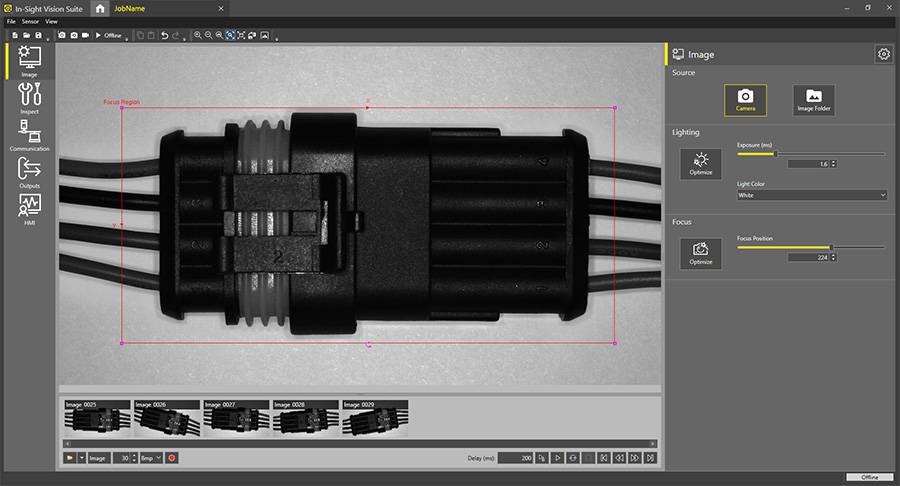

Common software platform offers flexible development options

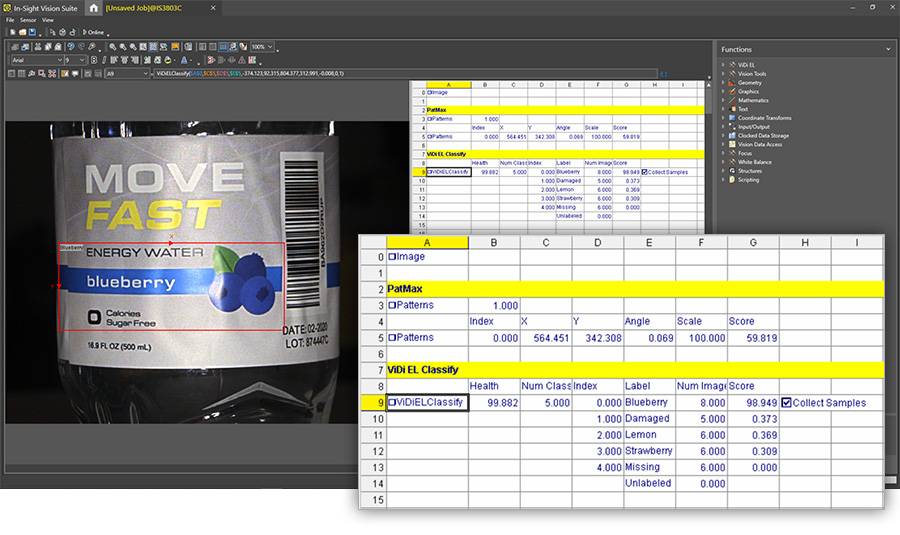

In-Sight Vision Suite software is common across all In-Sight products and includes two programming environments – EasyBuilder® and spreadsheet – which allow you to seamlessly scale your solution as your application needs change.EasyBuilder simplifies setup and delivers rapid turnaround

Spreadsheet facilitates deployment of advanced applications

Extensive toolset addresses tasks of varying complexity

Easy-to-use edge learning brings the power of AI to everyone

ViDi EL Classify

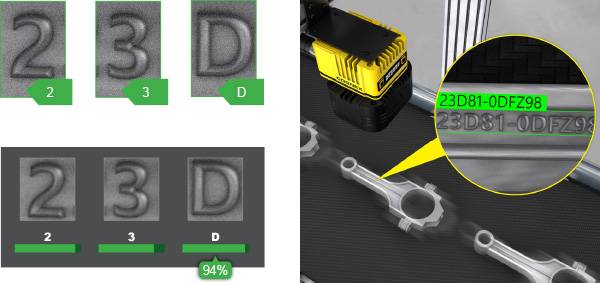

ViDi EL Read

- Pre-trained mode – allows you to read characters right out of the box for simple applications

- User-trained mode – allows you to train characters to solve more complex applications

Dome Cover

Multi Torch Cover

Power Cables

Ethernet Cables

Universal Mounting Bracket

Converter Mounting Bracket

Flat surface mounting plate adapter for Multi Torch configuration

Red Bandpass Filter

Blue Bandpass Filter

In-Sight 3800 helps you lead with speed across all industries by automating a wide range of inspection applications, at the fastest speeds. With modular hardware and an extensive tool set, In-Sight 3800 offers an industry-agnostic solution that allows you to maximize throughput and improve the accuracy of your results, regardless of the task at hand.

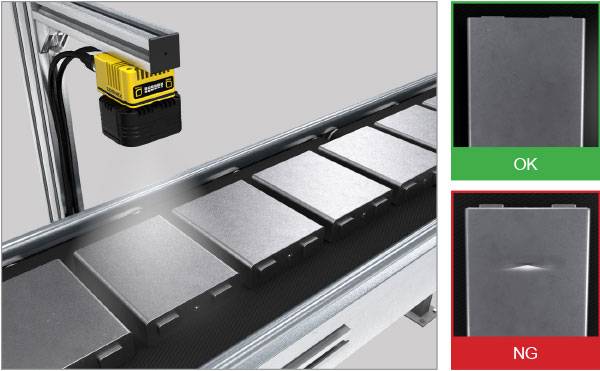

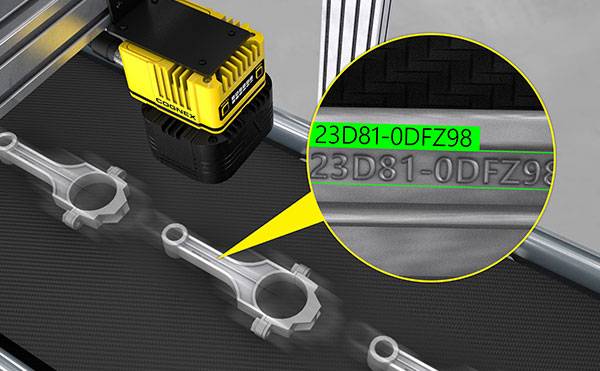

Automotive and EV

EV Battery Pouch Inspection

Identify surface-level defects, such as scratches, dents and tears, and generate pass/fail results.

Connecting Rod Identification

Decipher hard-to-read text etched on metallic surfaces to ensure proper routing and traceability.

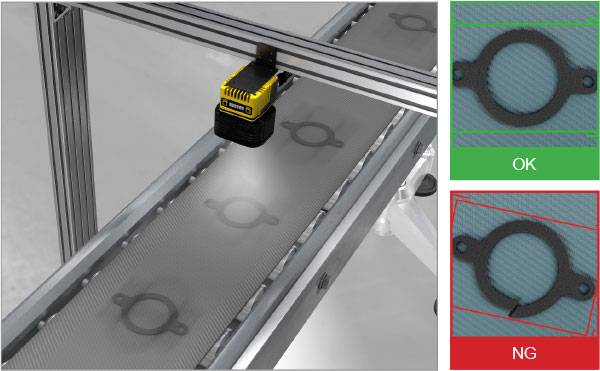

Gasket Quality Check

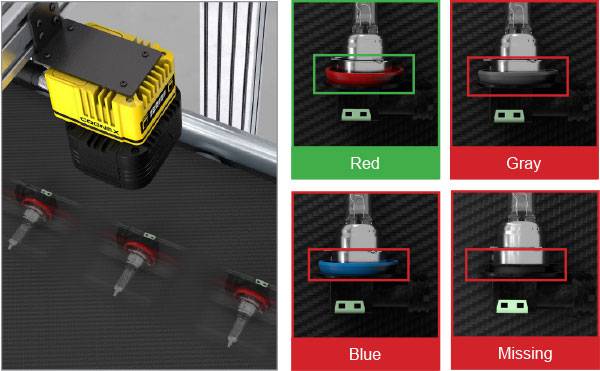

O-Ring Detection and Classification

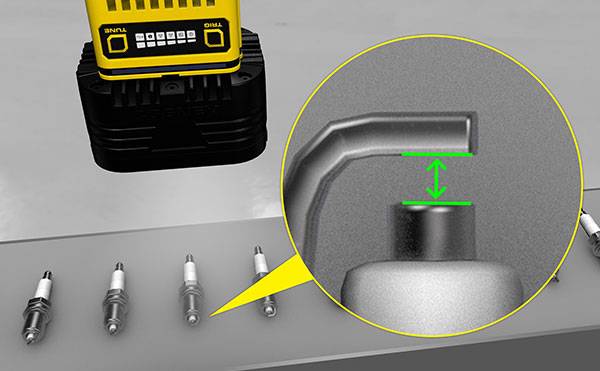

Spark Plug Gauging

Tire Identification

Consumer Packaged Goods

Detergent Bottle Label Reading

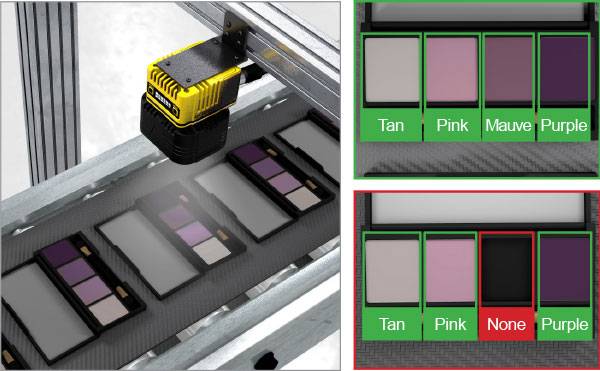

Makeup Palette Inspection

Robotic Guidance for Pick and Place

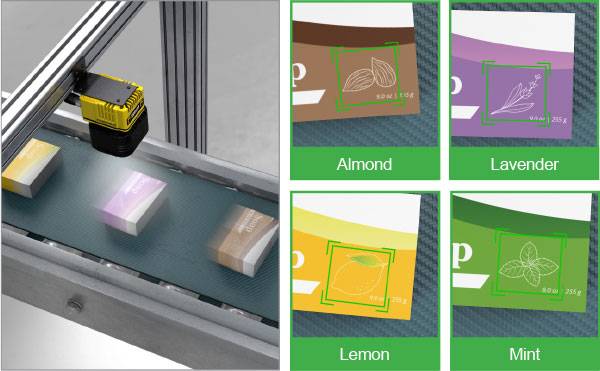

Soap Box Scent Classification

Electronics

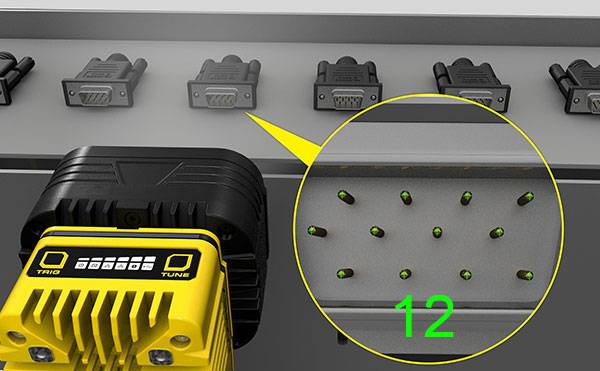

Cable Pin Count

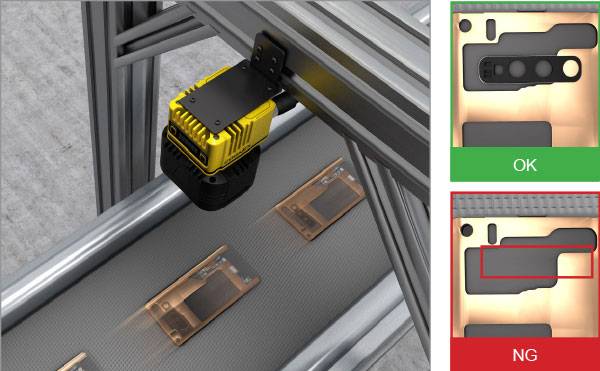

Smartphone Assembly Inspection

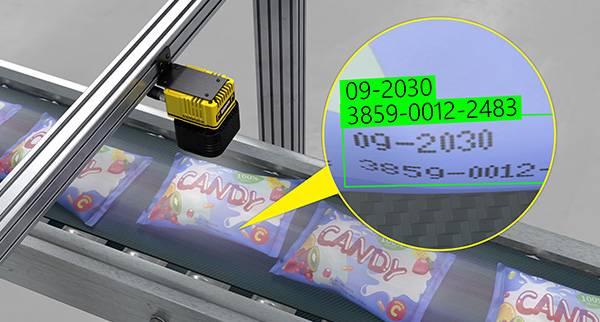

Food and Beverage

Barcode Reading on Bottles

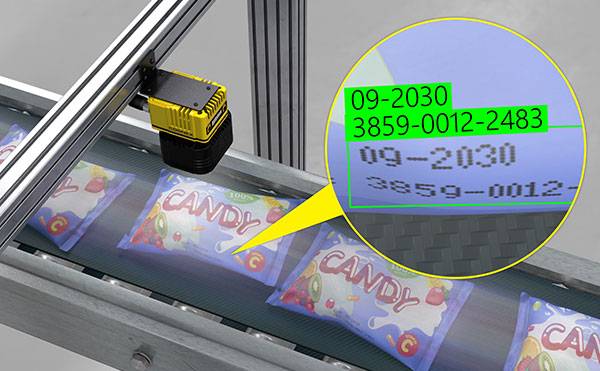

Lot Code and Expiration Date Reading

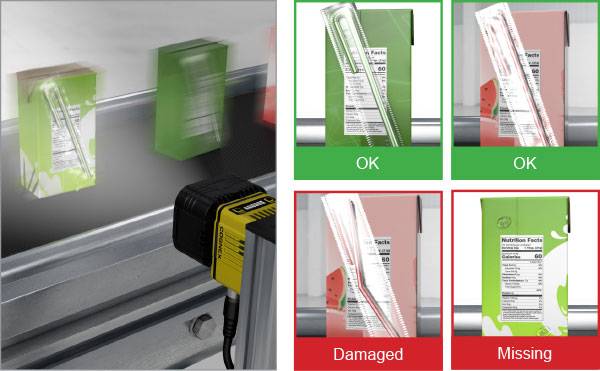

Juice Box Inspection

Logistics

Package Traceability

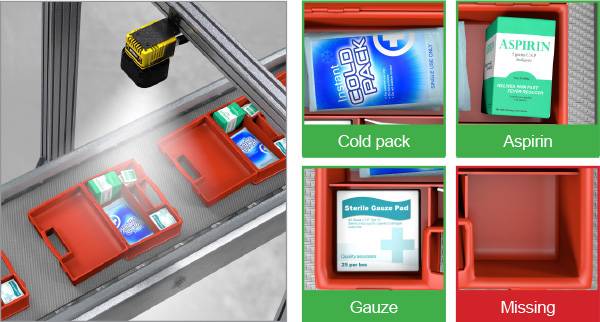

Pharmaceutical and Medical Device

Medical Device Code Reading and Text Recognition

Vaccine Label Inspection

FEATURED COGNEX PRODUCTS

INTRODUCE

VISION SENSOR

IN-SIGHT VISION SYSTEM

IN-SIGHT 7000