- Machine Vision

- Vision Sensor

- 2D Machine Vision System

- Vision Tools

- 3D Machine Vision System

- OEM Products

- Barcode Reader

Vision made simple

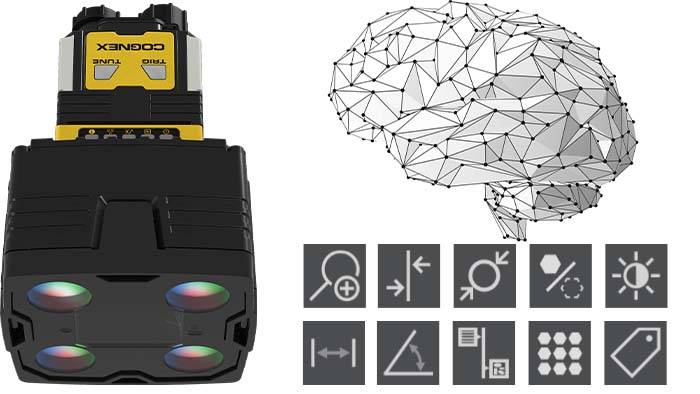

The In-Sight 2800 vision system combines artificial intelligence (AI) with traditional rule-based vision tools to solve a wide range of applications. From presence/absence detection to sortation and character reading, In-Sight 2800 provides an easy to deploy solution for error-proofing.

Designed for factory automation, In-Sight 2800 enables manufacturers of all sizes to:

- Increase product quality – Catch small, subtle defects with optimized error detection.

- Maximize operational efficiency – Leverage your existing workforce and keep your lines running with fast, intuitive job setup.

- Streamline integration – Take the guesswork out of image optimization and identify the correct combination of accessories in a few button clicks.

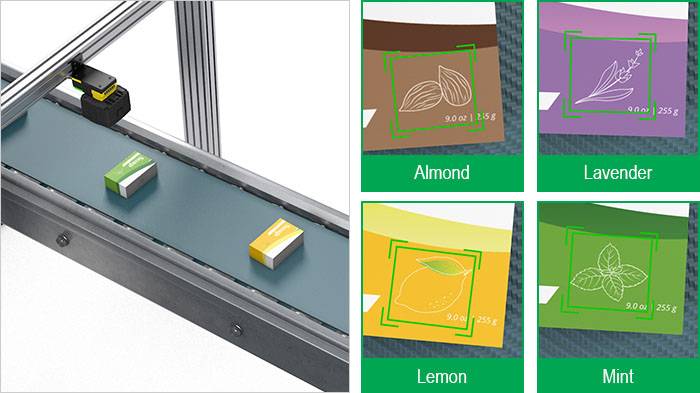

Unlimited classification outputs and regions of interest provide ultimate flexibility

Advanced optical character recognition deciphers a range of text

Advanced optical character recognition deciphers a range of text

Comprehensive vision toolset addresses tasks of varying complexity

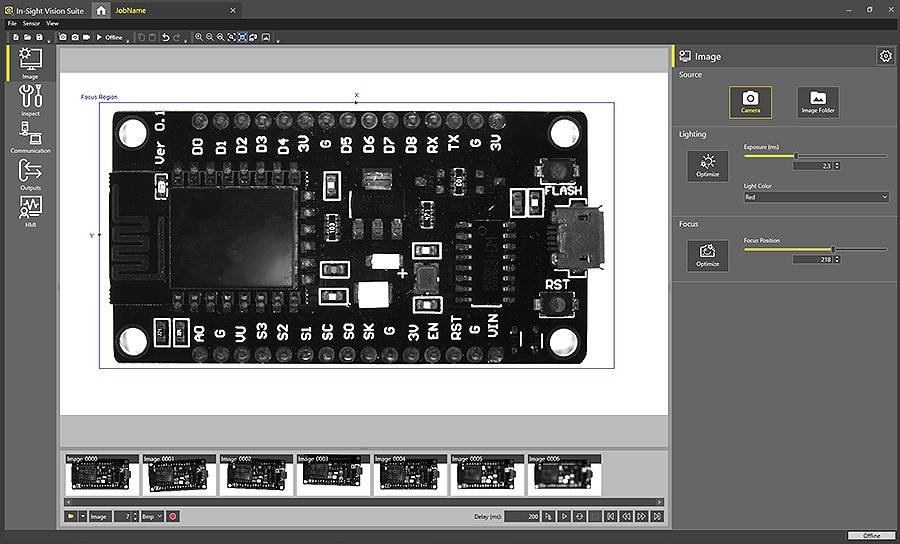

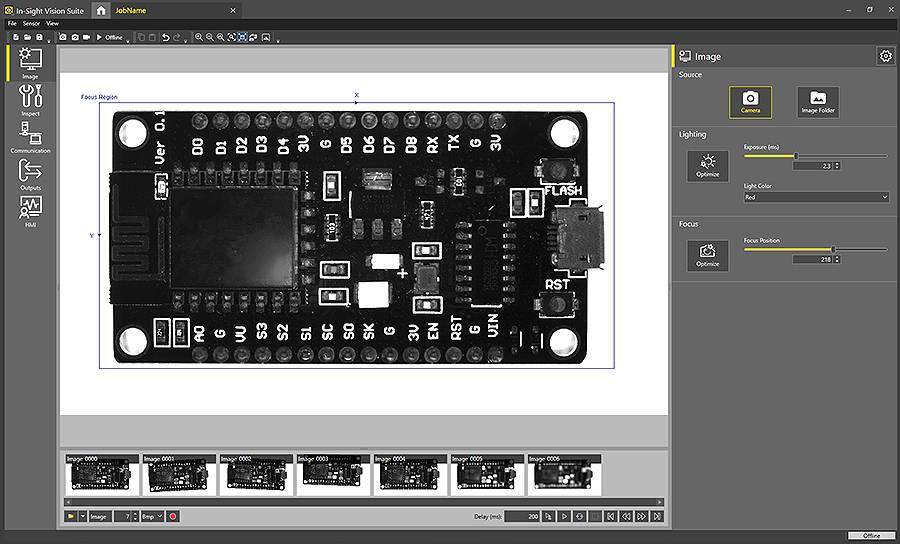

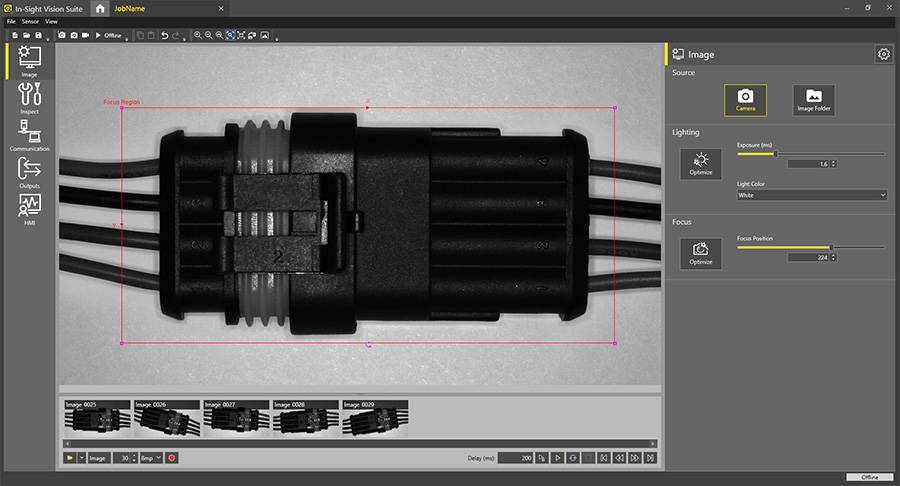

EasyBuilder development environment simplifies setup and offers rapid turnaround

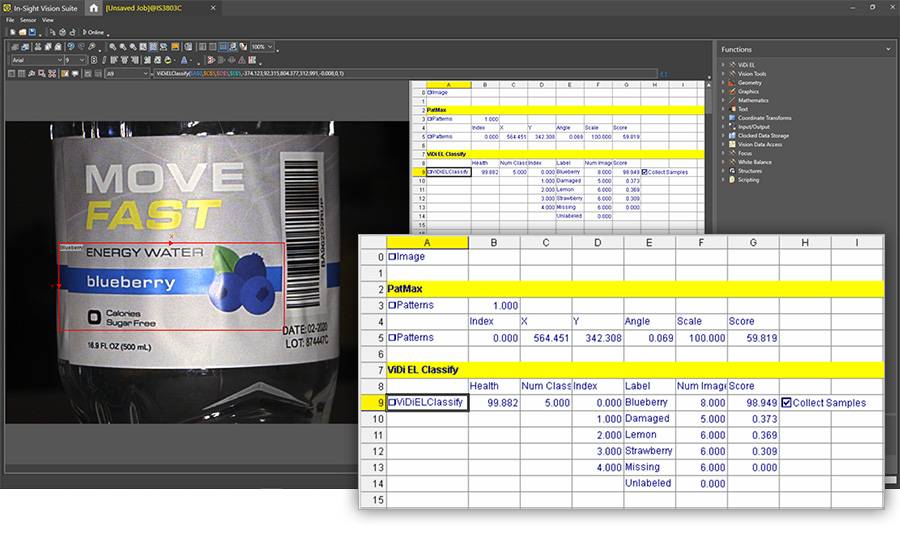

Spreadsheet interface for advanced applications

Powerful and flexible integrated lighting for enhanced images

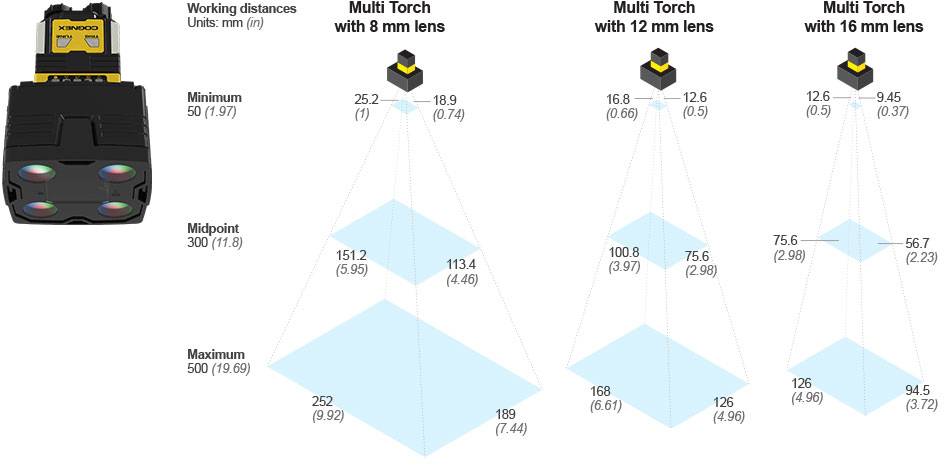

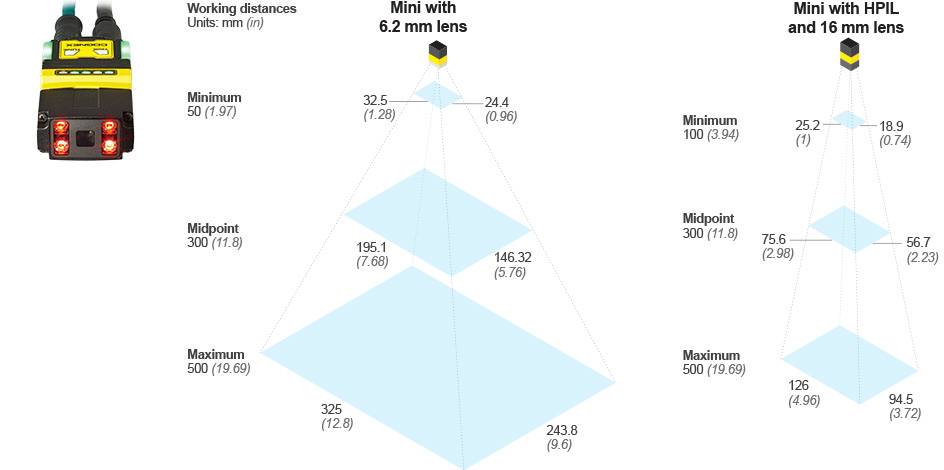

Capture high-resolution images of any product in any environment. Multi-color lighting (RGBW) optimizes image formation, maximizing contrast and illumination, regardless of operating conditions.

Powerful imaging technology offers improved accuracy

Modular, scalable architecture for current and future needs

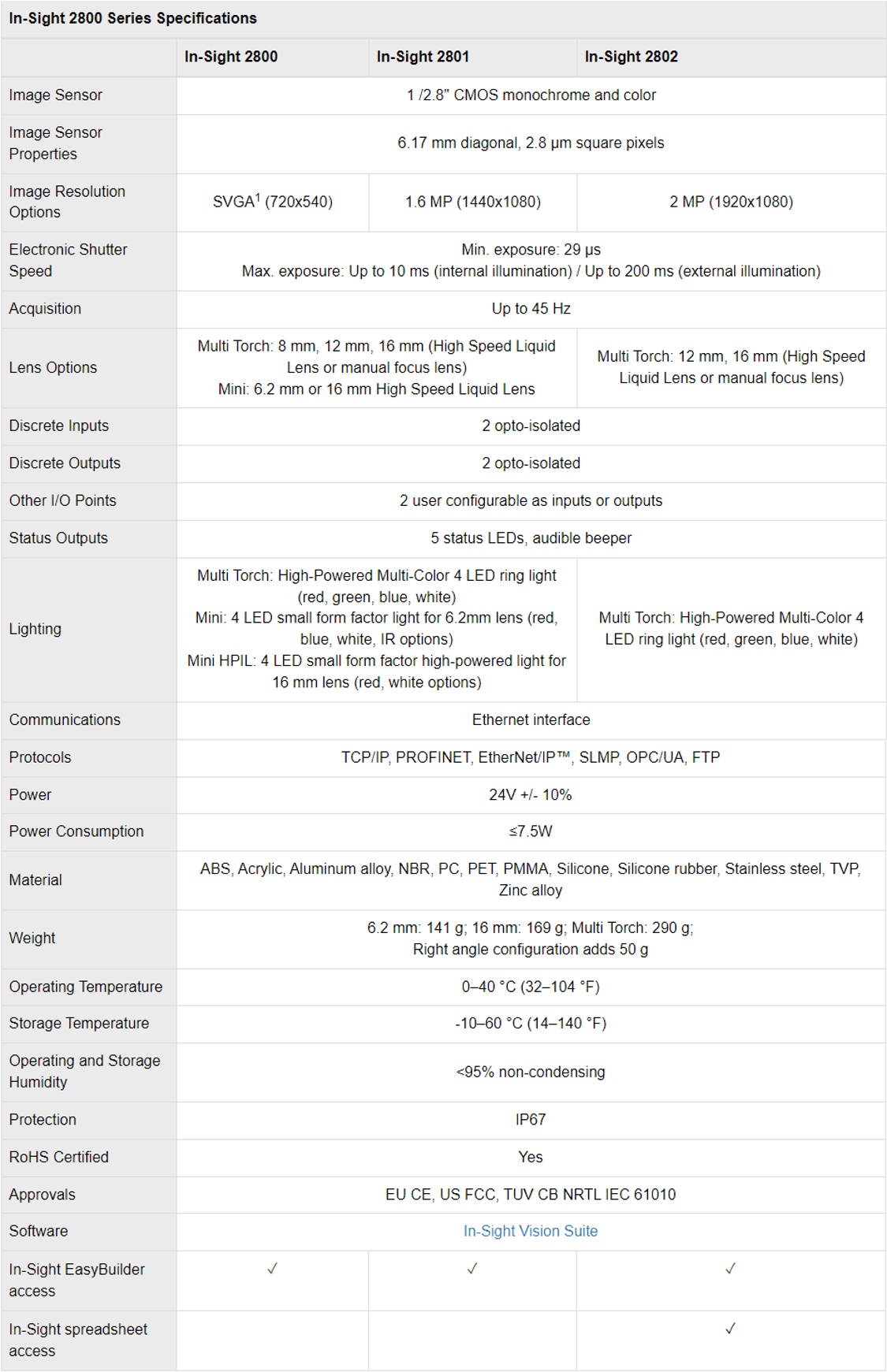

In-Sight 2802 with Multi Torch

In-Sight 2800/2801 with Multi Torch

In-Sight 2800/2801 Mini

EasyBuilder simplifies setup and delivers rapid turnaround

Spreadsheet facilitates deployment of advanced applications

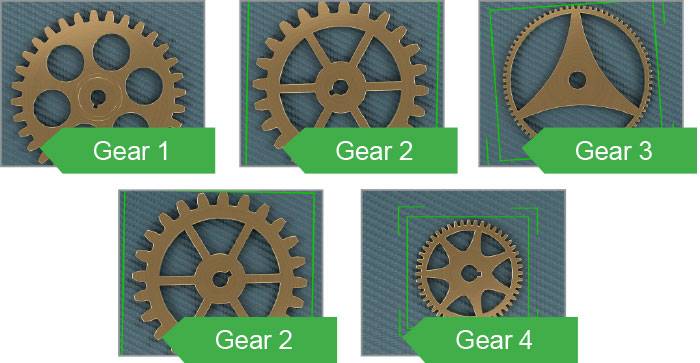

ViDi EL Classify

ViDi EL Classify

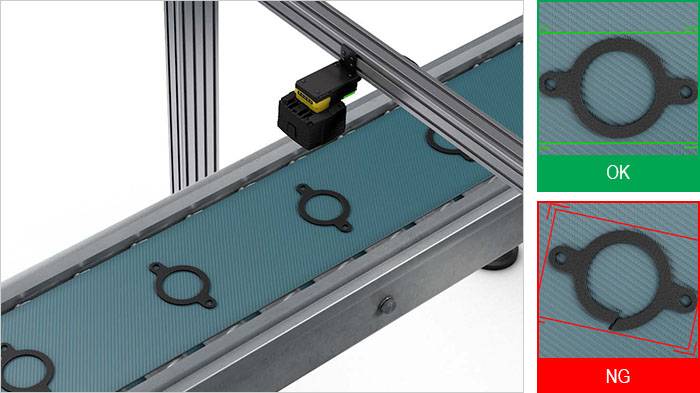

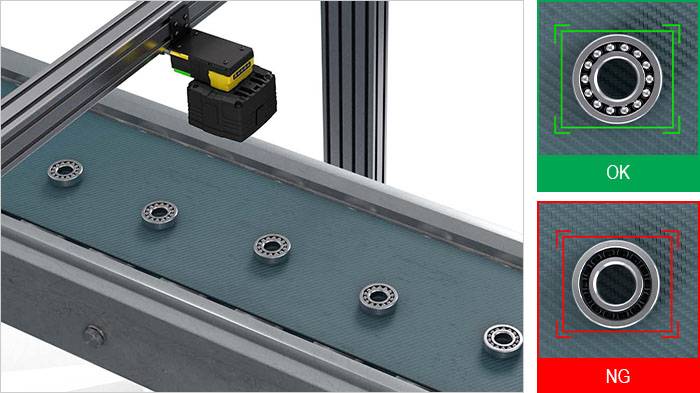

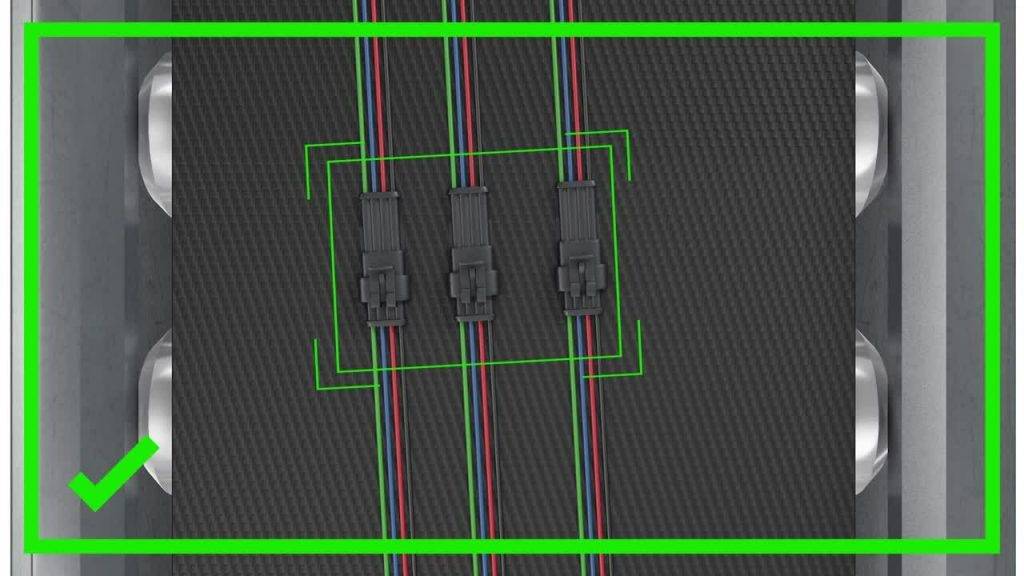

The ViDi EL Classify tool uses edge learning to automatically identify and sort objects into classes based on multiple defect types or user-defined features. Within the same class of objects, this advanced classifier is capable of discerning visually similar, but different objects. From as simple as OK/NG all the way to classifying parts with variation, ViDi EL Classify can be used to detect errors for a wide range of products.

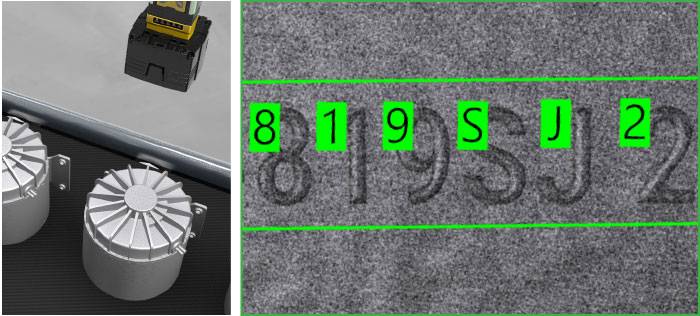

ViDi EL Read

ViDi EL Read

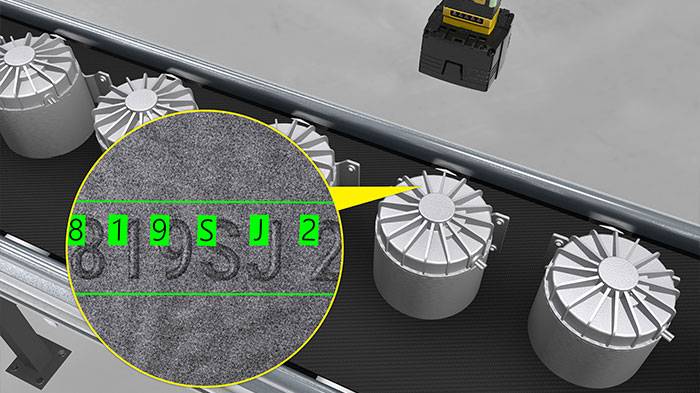

The ViDi EL Read tool deciphers a variety of text and font types using advanced optical character recognition (OCR). It reads multi-line text, as well as characters against challenging backgrounds, including reflective, low-contrast, and non-flat surfaces. ViDi EL Read can also be quickly redeployed to handle new text and accommodate process variations. With minimal training required, the tool simplifies job setup and delivers fast, accurate character reading.

Dome Cover

Multi Torch Cover

Power Cables

RS-232 Connection Cable

Ethernet Cables

X-coded to A-coded Ethernet Cable Adapter

Universal Mounting Bracket

Pivot Mounting Bracket

Flat surface mounting plate adapter for Multi Torch configuration

Red Bandpass Filter

Blue Bandpass Filter

Automotive and EV

Gasket Quality Check

Ball Bearing Check

Ball Bearing Check

Connector Insertion Check

Connector Insertion Check

Part Identification

Part Identification

Consumer Packaged

Scent Classification

Scent Classification

Air Freshener Quality Check

Air Freshener Quality Check

Label Detection

Label Detection

Electronics

PCB Component Check

PCB Component Check

Food and Beverage

Bottle Seal Check

Serving Scoop Detection

Serving Scoop Detection

Soup Can Code Reading

Soup Can Code Reading

Pharmaceutical

Blister Pack Quality Check

Vaccine Label Inspection

Logistics

Packaging Traceability

FEATURED COGNEX PRODUCTS

INTRODUCE

VISION SENSOR

IN-SIGHT VISION SYSTEM

IN-SIGHT 7000