- Machine Vision

- Vision Sensor

- 2D Machine Vision System

- Vision Tools

- 3D Machine Vision System

- OEM Products

- Barcode Reader

Solve the most challenging vision applications with AI-based automation

Read challenging characters and text in minutes

The In-Sight D900 deciphers badly deformed, skewed, and poorly etched codes using optical character recognition. Equipped with a pre-trained font library, the read tool works right out of the box, drastically reducing development time. Simply define the region of interest and set the character size. In situations where new characters are introduced, the tool can be easily retrained to read application-specific characters.

Perform fast and accurate assembly verification

The In-Sight D900 uses AI to reliably detect complex features and objects and verifies parts and kits are assembled correctly based on their location within a pre-defined layout. The check tool can be trained to recognize an extensive number, and variety, of components, which can be located in the image even if they appear at different angles or vary in size.

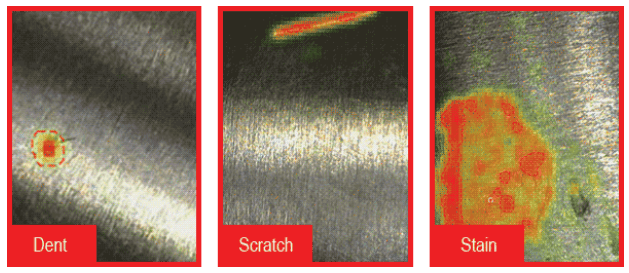

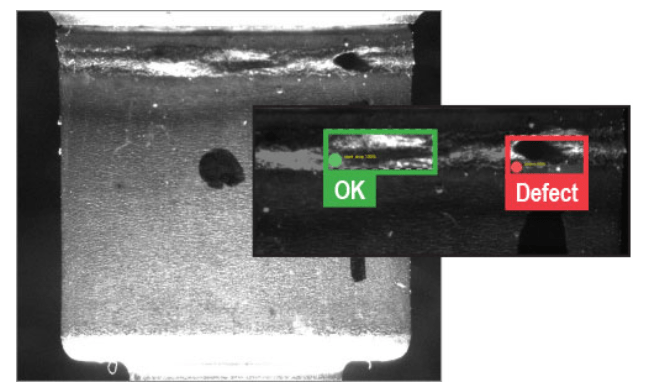

Detect and analyze subtle defects

The detect tool embedded within the In-Sight D900 is ideal for finding anomalies on complex parts and surfaces, even in situations where defects can be unpredictable in their appearance.

See the In-Sight D900 in 360 degrees

Get a closer look at the advanced features the In-Sight D900 has to offer in a fully interactive guided 3D tour.

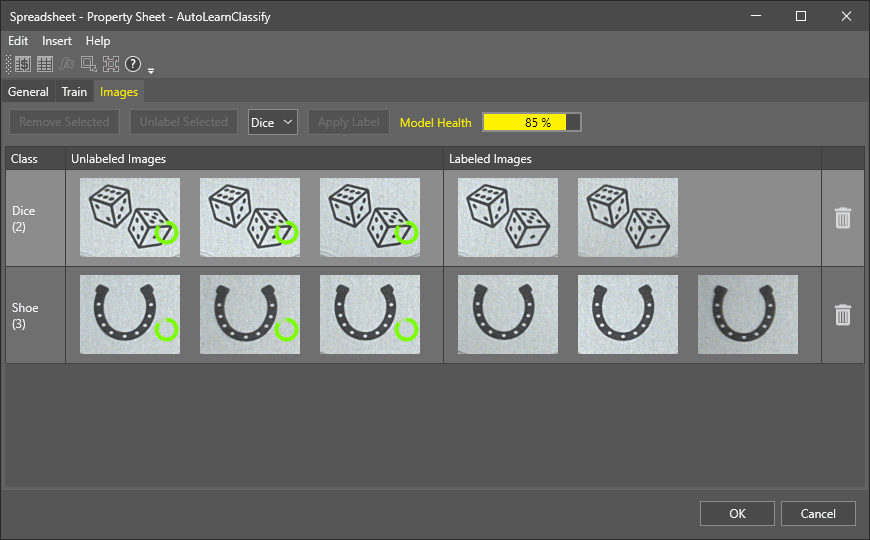

Precisely classify any defect

Precisely classify any defect

The classify tool leverages AI to automatically identify and sort defects into classes. Within the same class of objects, it discerns visually similar, but different defects to determine whether they are true defects or acceptable abnormalities.

Solve simple classification problems quickly and easily

Solve simple classification problems quickly and easily

The In-Sight D900 is embedded with powerful edge learning tools that leverage AI technology to learn “on the edge,” in real time, delivering fast, accurate results. The tools are simple to setup, requiring smaller image sets and shorter validation periods than traditional deep learning. They can be trained in minutes using as few as five to ten images per class with no coding required. This makes them an accessible automation solution for a range of users and skill levels.

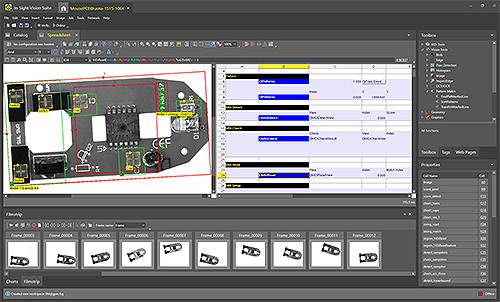

Quickly setup and deploy applications with In-Sight spreadsheet

Quickly setup and deploy applications with In-Sight spreadsheet

With an intuitive interface and a full communications function set, In-Sight spreadsheet simplifies application development and streamlines factory integration. It also allows you to combine rule-based and AI vision tools in the same project, leading to quicker deployments and faster cycle times.

Address your current and future needs with hardware modularity

Address your current and future needs with hardware modularity

Highly flexible in design, the In-Sight D900 includes field-changeable lighting, lenses, filters, and covers that can be customized to match your exact application requirements. It also includes an embedded inference engine that solves complex tasks at production line speeds.

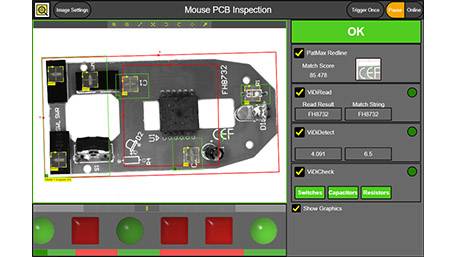

Precisely classify any deSimplify training and deployment with intuitive web-based HMI

fect

Precisely classify any deSimplify training and deployment with intuitive web-based HMI

fect

The In-Sight D900 vision system offers mobile, platform independent visualization for accessing HMIs (human machine interfaces) through In-Sight software. A simple point-and-click interface allows customers to build highly interactive, web-based HMIs remotely that are accessible via a web browser over the network.

Autofocus lens

Automatically moves in and out to focus on the target part eliminating manual intervention by the user. Ideal for inspecting parts on the same line that vary in size or distance from the lens, speeding up inspections and simplifying line changeover.

C-mount lens

Manually-adjusted, high-performance lens offers the most flexibility in terms of lens size, aperture and focus. Provides even resolution throughout the entire field of view, making this the most widely-used lens type.

Integrated lighting module

Incorporates Flexible Image Technology™ (FIT™) that optimizes image formation and minimizes the need for expensive external lighting. Field-changeable and user-configurable lighting and optics modules provide users with ultimate flexibility to customize the system for their application. Offers individually controlled diffuse illumination ideal for inspecting parts at varying working distances.

Filters

Offers individually controlled diffuse illumination ideal for inspecting parts at varying working distances.

Covers and integrated light module cover options

Standard and extended C-mount lens covers are available for use when no integrated lighting module is required. Additionally, wider diameter C-Mount covers are available for the 5MP 7000 (IS7905). These covers are used for C-Mount lenses only, not with the integrated lighting module or autofocus module. Optional polarizing and clear (without diffuser) covers are available for use with the integrated lighting module.

Cables

X-coded, power I/O and external light cables available.

In-Sight D900 is a powerful deep learning software platform designed specifically to solve applications that are too difficult, complex, or expensive for traditional machine vision systems. With an easy-to-use interface, In-Sight D900 eliminates complex programming, making deep learning technology accessible for non-vision experts, and automates inline inspections previously only possible with human inspectors.

In-Sight ViDi Read Tool

In-Sight ViDi Read Tool

In-Sight ViDi Check Tool

In-Sight ViDi Check Tool

In-Sight ViDi Detect Tool

In-Sight ViDi Detect Tool

In-Sight ViDi Classify Tool

In-Sight ViDi Classify Tool

FEATURED COGNEX PRODUCTS

INTRODUCE

VISION SENSOR

IN-SIGHT VISION SYSTEM

IN-SIGHT 7000