- Machine Vision

- Vision Sensor

- 2D Machine Vision System

- 3D Machine Vision System

- OEM Products

- Barcode Reader

In-Sight 2000 Vision Sensor Features

Cognex In-Sight 2000 vision sensors combine the power of In-Sight vision systems with the simplicity and affordability of an industrial sensor. Ideal for solving error-proofing applications, these vision sensors set new standards for value, ease of use, and flexibility and can adapt to virtually any production line environment. Key features include:

- Powerful In-Sight vision tools

- Easy setup with EasyBuilder

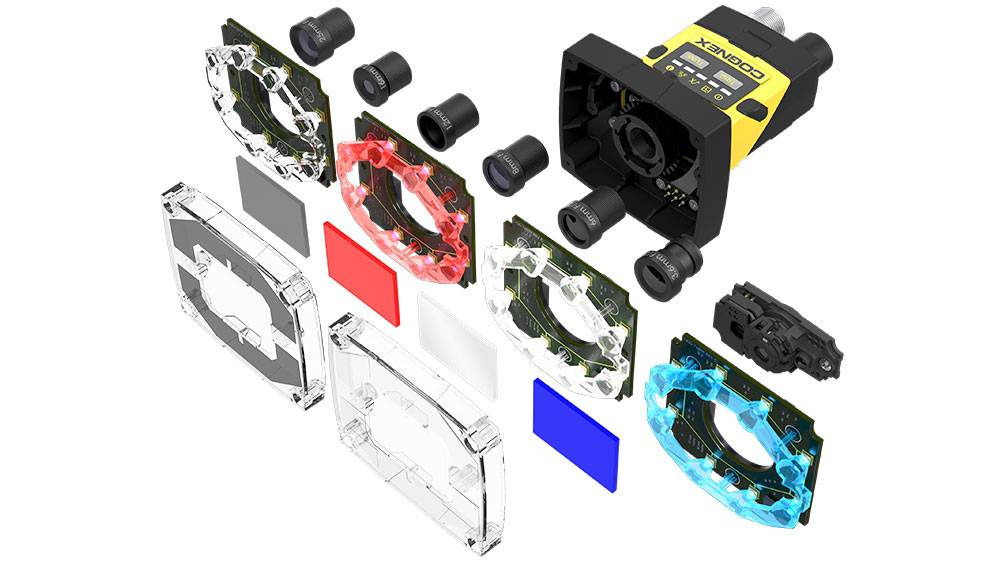

- Field interchangeable lighting and optics

- Modular body design

Add Your Heading Text Here

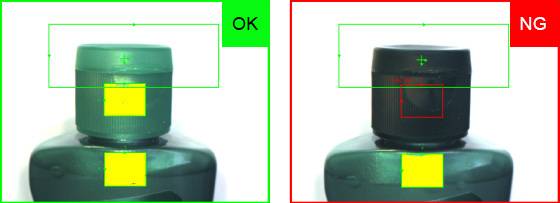

Proven In-Sight vision tools–including pattern, pixel count, brightness, contrast, and edge tools—solve simple location, presence/absence, measurement, and counting applications. In-Sight 2000 vision sensors can inspect multiple targets within a single image, as well as perform multiple inspection types relying on different tools. When increased functionality or capability is required, Cognex offers models with toolsets that include image filters, OCR, blob, and numeric data output and models with resolution up to 1280 x 960 (1.2MP).

Easy Set-Up with EasyBuilder

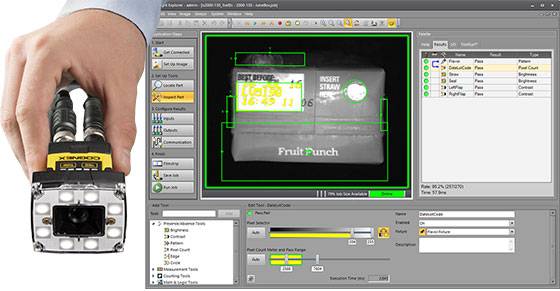

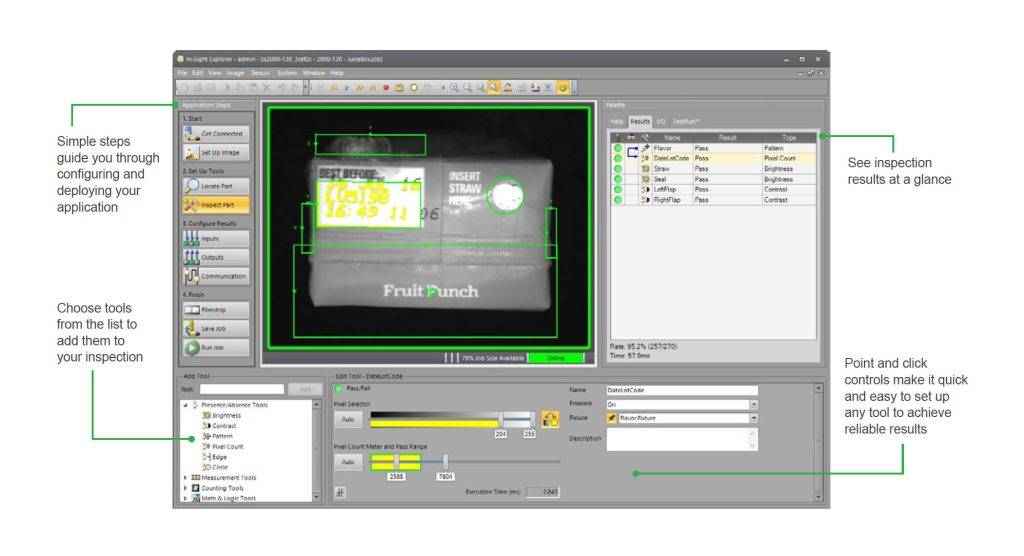

Even novice users can achieve reliable inspection performance using In-Sight Explorer software with EasyBuilder’s simple, intuitive interface—the same one used in all In-Sight vision systems. For more complex pass/fail and go/no-go inspections, users can build on their experience to create vision applications using more advanced In-Sight vision systems in the same In-Sight Explorer interface.

Modular Body and Lighting

The In-Sight 2000 series features a modular design with field changeable lights, lenses, filters and covers that make it easy to choose the correct configuration for your work cell. A modular body design:

- Provides maximum flexibility to mount in tight spaces

- Simplifies wiring and optical paths

- Minimizes the need to design new mechanical fixtures

Configurable in-line or right-angle mounting provides maximum flexibility in tight spaces. An integrated, patent-pending LED ring light produces even, diffuse illumination across the entire image, minimizing the need for costly external lighting.

In-Sight 2000 Vision Sensor Software

Technology and application requirements for automated inspections are constantly evolving. This standardized environment is used to configure and maintain all machine vision applications, including for advanced In-Sight vision systems. The In-Sight 2000 offers a standardized set-up environment, powerful vision technology, and a reliable communications link that make it easy to configure applications and connect to other factory automation equipment.

Fast, Intuitive Set-Up with EasyBuilder

All In-Sight 2000 vision sensors use In-Sight Explorer EasyBuilder to set up and monitor machine vision inspections. The intuitive, point-and-click interface guides users through a step-by-step setup process for easy application development. With EasyBuilder, even novice vision users can easily set up, configure, and install a vision sensor. The TestRun validation utility for In-Sight Explorer helps ensure that the reliability of inspections won’t change, even when conditions do, by monitoring whether programming changes have affected the system.

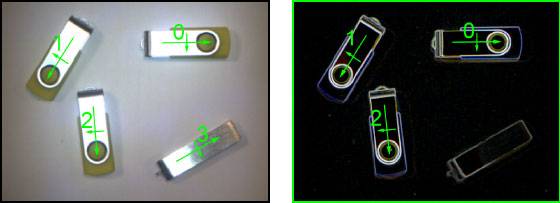

Powerful location, presence/absence, measurement, and counting tools can be configured directly within the EasyBuilder interface, making it easy to set up and solve pass/fail and go/no go inspections.

Trusted Vision Tools

Cognex’s pattern, pixel count, brightness, contrast, and edge tools enable the In-Sight 2000 to perform advanced presence/absence, measurement, and counting applications. Using these tools, the In-Sight 2000 can inspect multiple targets within a single image, as well as perform multiple inspection types relying on different tools. Pattern, edge, and circle tools locate (or fixture) the part so other vision tools can use this as a reference to complete their inspections. The In-Sight 2000-230 models also include image filters, OCR, blob, and numeric data output.

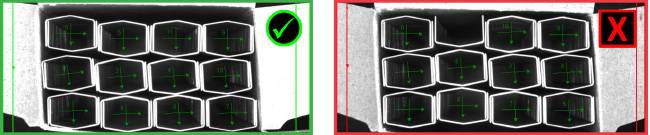

Pattern tool verifies that the correct number of staple strips have been added to a carton.

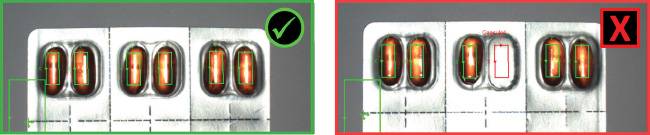

Brightness tool confirms the presence of all 10 capsules by showing the greatest delta between pass/fail areas.

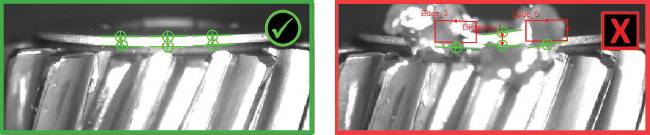

High contrast in the target area indicates the presence of a diode.

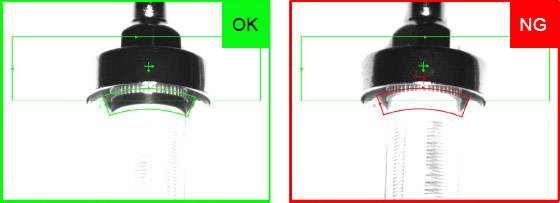

Multiple edge tools measure pixels to detect a clean edge on a drill burr.

Pixel count tool confirms the presence of 13 separate hole punches within one target by determining pixel value.

Color pixel count tool confirms the integrity of packaging by identifying pixel values of colors trained in the region of interest.

Lighting & Lens Filters

A white LED ring light with diffuser cover is standard on most In-Sight 2000 models. Field interchangeable red, blue and IR ring lights and lens filters are also available.

Light Covers

An optional polarizer cover works with the white LED ring light to reduce undesirable reflections on shiny part surfaces. A clear cover is also available to increase image brightness in longer distance applications.

Lenses

An 8 mm S-Mount/M12 lens is standard on most In-Sight 2000 models. Field interchangeable 3.6 mm, 6 mm, 12 mm, 16 mm, 25 mm S-Mount/M12 lens options are also available.

Mounting Brackets

Multiple brackets and adapters are available for mounting an In-Sight 2000 vision sensor at nearly any point of inspection on the production line. And IP670-rated enclosure is also available for installation in washdown areas and other harsh environments

I/O and Cables

Network, power and I/O cables are available in several lengths. And when additional I/O is needed, the CIO-1400 I/O Expansion module extends the capabilities of In-Sight 2000 series vision sensors with 7 general purpose inputs and 8 outputs.

Power Supply

A compact, DIN-rail mount 24 volt DC power supply is available.

In-Sight 2000 Web-Based HMI

Cognex In-Sight 2000 vision sensors offer secure, mobile, platform independent visualization. A simple point-and-click interface allows customers to build interactive, web-based HMIs remotely accessible via a web browser over the network. With In-Sight 2000, operators can now view inspections, controls engineers can modify parameters or load/save jobs, and plant managers can review performance statistics.

VisionView Display Panel

The VisionView 900 interface panel monitors and controls In-Sight 2000 vision sensors on the factory floor. Operators can log on to the In-Sight 2000 and take it online or offline to load a job. A red or green LED indicator displays pass/fail results.

The VisionView display panel features:

- Password-protected operator access

- Nine-inch/229mm touch screen

- LAN port with an external switch to connect up to nine systems

- Two USB ports to save failed images or connect a mouse or

- keyboard

- Change inspection job and tool settings

Electronics

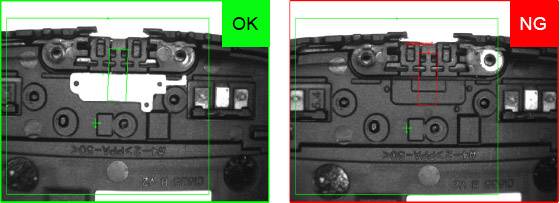

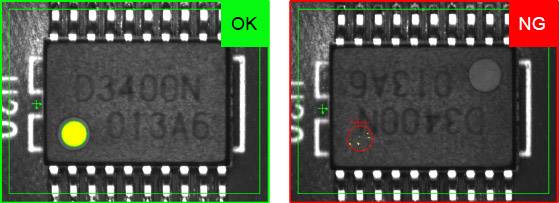

Edge Tool: The presence of a rubber gasket attached to a molded plastic part is verified before an automated final assembly step.

Pixel Count Tool: The presence of a fiducial is used to verify that an integrated circuit has been soldered onto the PCB in the correct orientation.

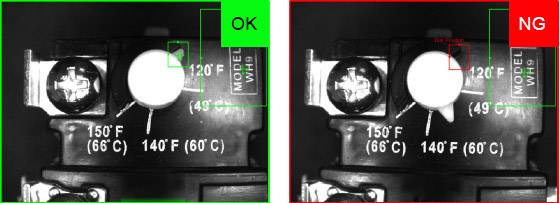

Pattern Tool: The dial on a thermostat is checked to confirm that it is in the correct position, which helps to ensure proper installation.

Image Filters: Image filters process images after acquisition in preparation for analysis.

Automotive

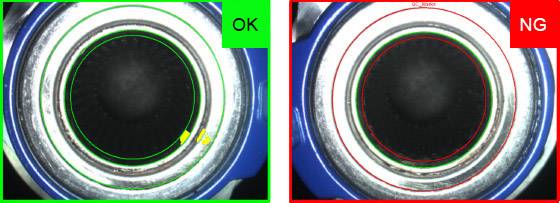

Brightness Tool: A fuel filter assembly is inspected for the presence of an O-ring installed in the proper location before final packaging.

Color Pixel Count Tool: A wheel hub bearing is checked for the presence of quality control (QC) marks before moving to the next stage of assembly. The absence of the QC marks indicates that the hub bearing has not yet been inspected.

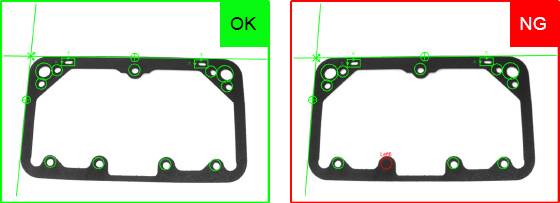

Pixel Count Tool: A fuel bowl gasket is inspected to verify that all 13 through holes have been punched out. A missing hole will cause the part to fail.

FEATURED COGNEX PRODUCTS

INTRODUCE

VISION SENSOR

IN-SIGHT VISION SYSTEM

IN-SIGHT 7000