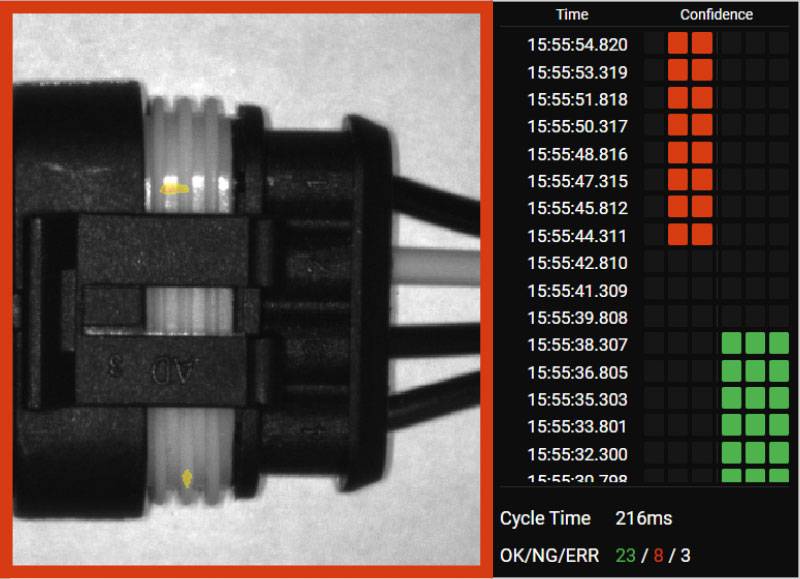

Get immediate, visual feedback on the performance of your sensor.

- Machine Vision

- Vision Sensor

- 2D Machine Vision System

- 3D Machine Vision System

- OEM Products

- Barcode Reader

Sensors, reimagined

The In-Sight SnAPP vision sensor brings the power of machine vision to everyone. With guided setup and pre-trained AI, In-Sight SnAPP allows manufacturers to quickly and easily automate inspections, no experience needed. Leveraging innovative vision technologies, these user-friendly sensors solve a wide range of error-proofing tasks to improve quality control.

- Flexible functionality – Address a variety of applications across all industries

- Superior detection capabilities – Achieve higher detection rates with embedded AI and image-based analysis

- High ease of use – Go from unboxing to automating your line in minutes

Automate activities across your facilities

In-Sight SnAPP Apps address a range of error-proofing tasks, from simple presence/absence detection to multi-point inspections. These sensors perform one job at a time but can solve a variety of different applications. Within the intuitive user interface, you can easily switch between applications to respond to changes on the line or create new jobs to automate more steps in your production process. This keeps your business agile, while reducing costs and eliminating manual errors.

- Anomaly Detector – Run anomaly detection and find variable defects and features, like stains, scratches, and debris

- 2-Class Classifier – Perform binary classification and inspections with known or consistent anomalies

Coming soon…

- Optical character recognition

- Assembly verification

- 4-class classification

- Counting

- Identification

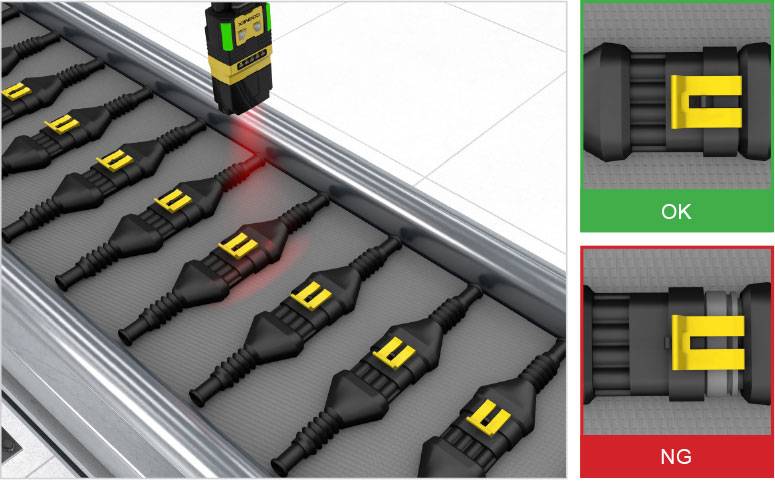

Go beyond standard detection

Powered by AI and image-based analysis, In-Sight SnAPP vision sensors exceed the capabilities of conventional, laser-based sensors to offer higher accuracy and higher performance for any detection task. In-Sight SnAPP allows you to do more than ever before with a sensor:

- Identify subtle features and anomalies

- Handle product variations and quickly respond to changes

- Run multi-point inspections

- Locate features and parts in any position on the line

All of this helps you to eliminate false detections, reduce waste, and optimize overall quality and productivity.

Solve problems with ease

In-Sight SnAPP allows anyone to automate quality control tasks. Leveraging pre-trained AI, applications can be built, quickly and easily, with no experience needed.

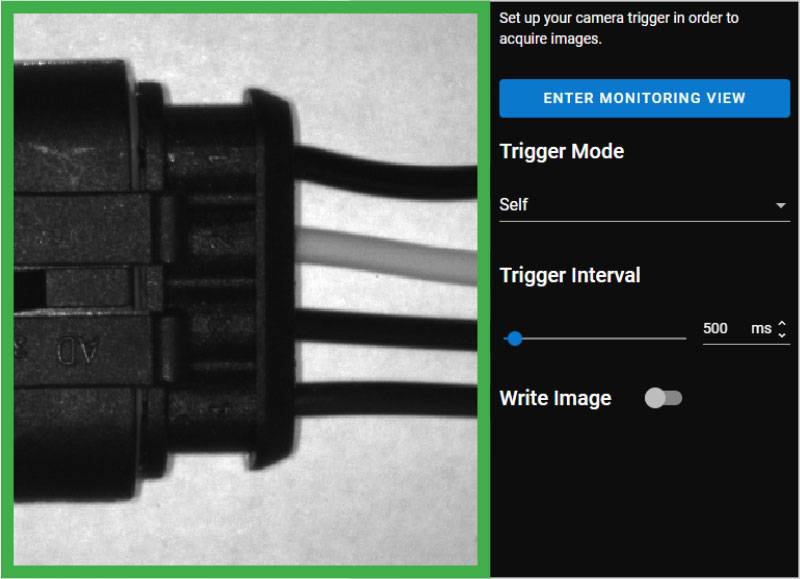

- Guided setup – Reduce downtime with fast, intuitive setup

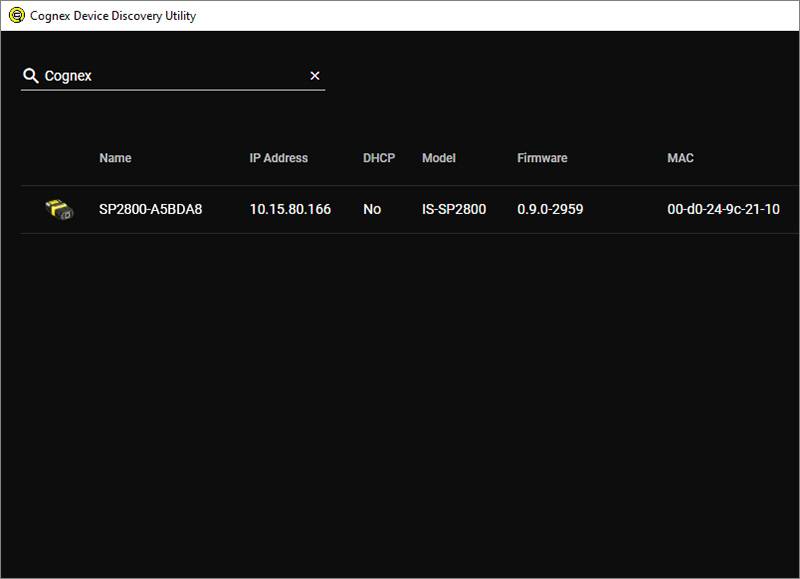

- Browser-based UI – Plug in and run In-Sight SnAPP from anywhere

- No code training – Train jobs using a few sample images

- Simplified deployment – Easily modify applications or build new ones within the UI, no hardware exchange needed

- Streamlined integration – Replace multiple laser-based sensors with one vision sensor

Solve problems with ease

VisionView is a display panel that allows you to quickly train, update, and monitor jobs on the production line, without the need for a PC. Having this technology on the factory floor improves efficiency, facilitates easy device management, and provides real-time feedback for immediate process improvements.

Additional Features

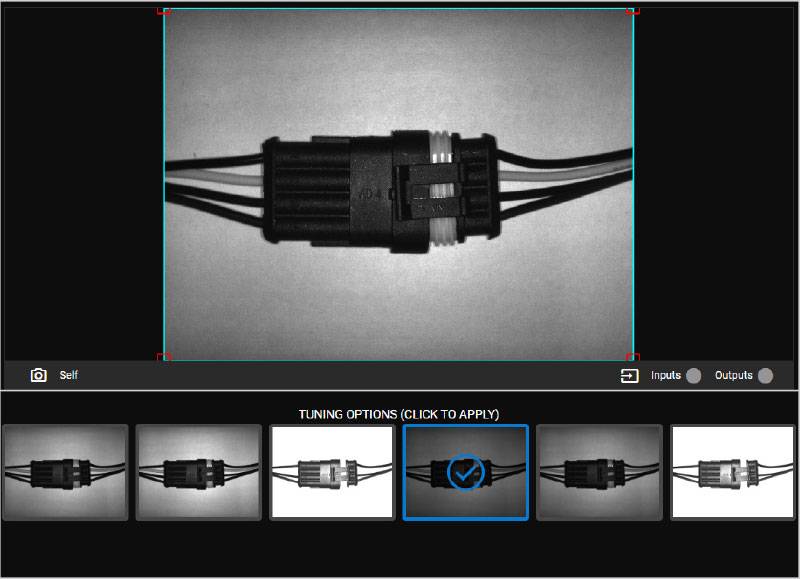

1-click image optimization

Capture high-resolution images, in a single click, for more accurate inspections.

Web HMI compatibility

Set up and audit applications – without a PC – using an intuitive display panel that allows you to update and monitor jobs, directly on the factory floor.

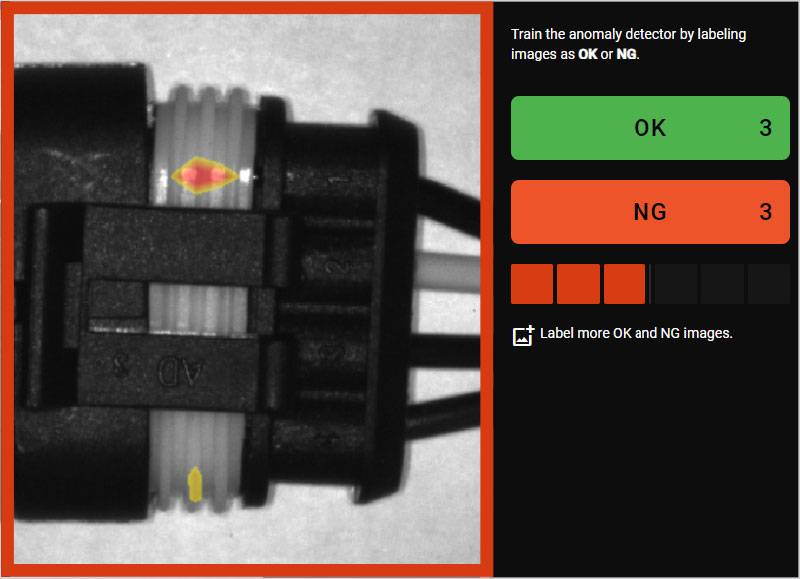

Real-time training feedback

View results in real-time to verify application performance and identify potential issues early in your production process.

Compact size

Easily add automation anywhere in your line with a small form factor.

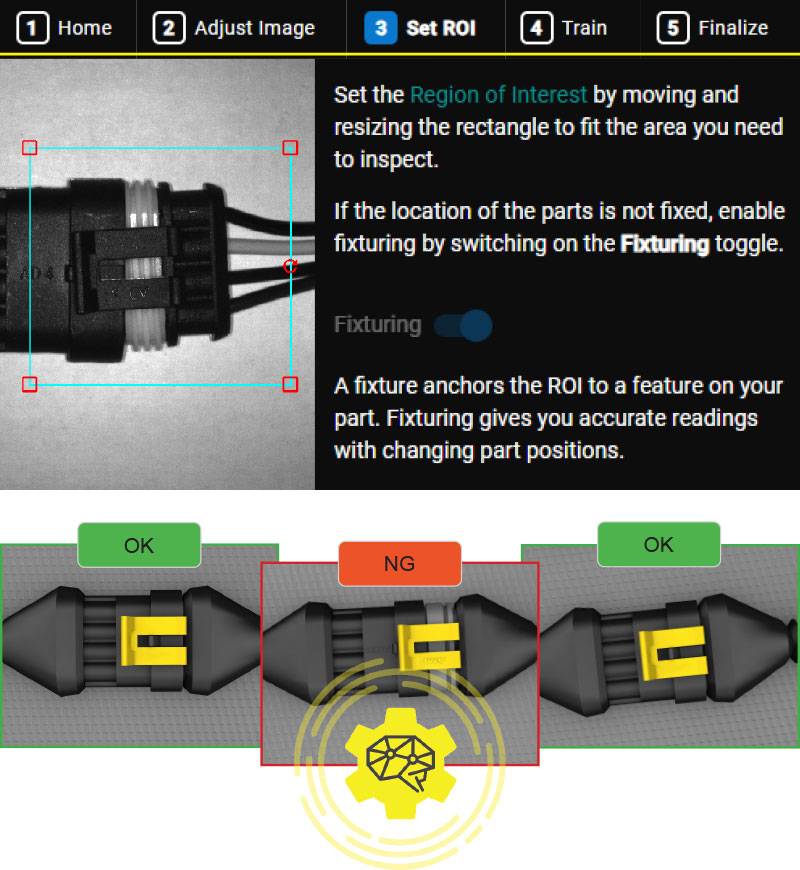

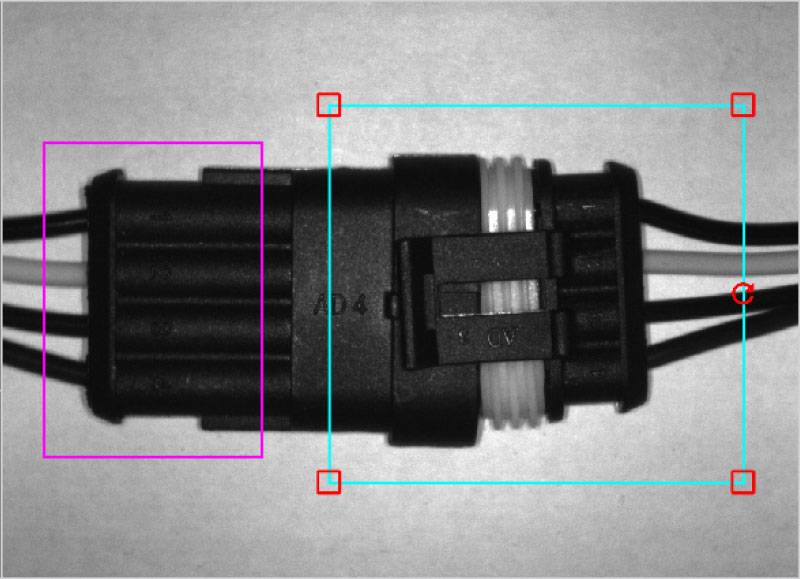

Fixturing capabilities

Fixture your region of interest to locate parts and features in any position – regardless of how parts come down the line – for consistent detection.

IP67 rated

Operate in even the most challenging manufacturing environments with a rugged design.

LED indicator

Take the complexity out of training

Take the complexity out of training

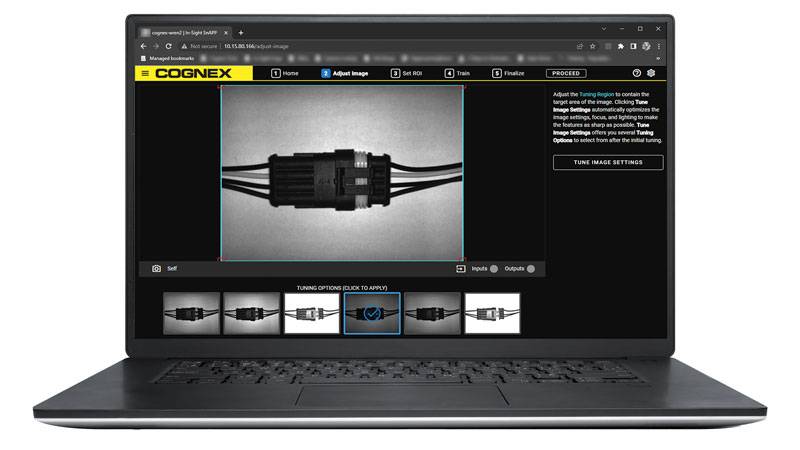

n-Sight SnAPP vision sensors are trained through a web-based user interface (UI), which eliminates the need to download and install software. Using the browser of your choice, you can access the training UI from anywhere and immediately begin building your application.

The user-friendly interface guides you step-by-step through setup, from image capture to final result. Jobs can be trained using just a few sample images and embedded AI takes care of the rest, learning to recognize anomalies and correctly predict the output.

Take the complexity out of training

Take the complexity out of training

Pre-setup: Find the device

Step 1: Open device and access the home screen

Step 2: Adjust image

Step 3: Set the region of interest

Step 4: Train

Step 5: Finalize

Post-setup: Enter monitoring view

Expand your automation possibilities

In-Sight SnAPP automates a wide range of quality control tasks, so you can be ready for anything. View the examples below to see how you can use this powerful, yet easy-to-use solution, to solve problems across your production line.

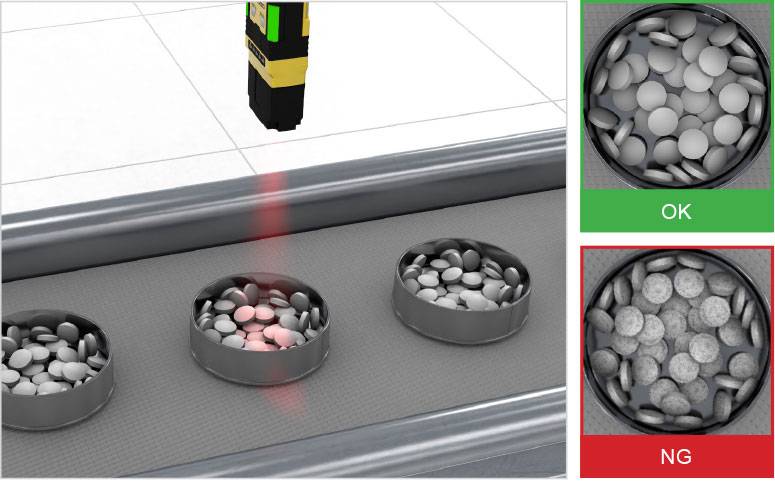

Anomaly Detector

Automotive

Verify proper assembly

Food & Beverage

Inspect packaged items for debris

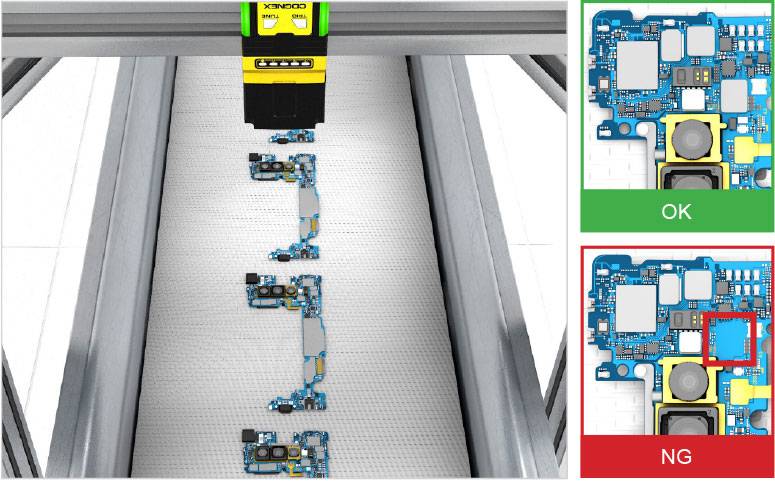

Electronics

Detect presence/absence of components during assembly

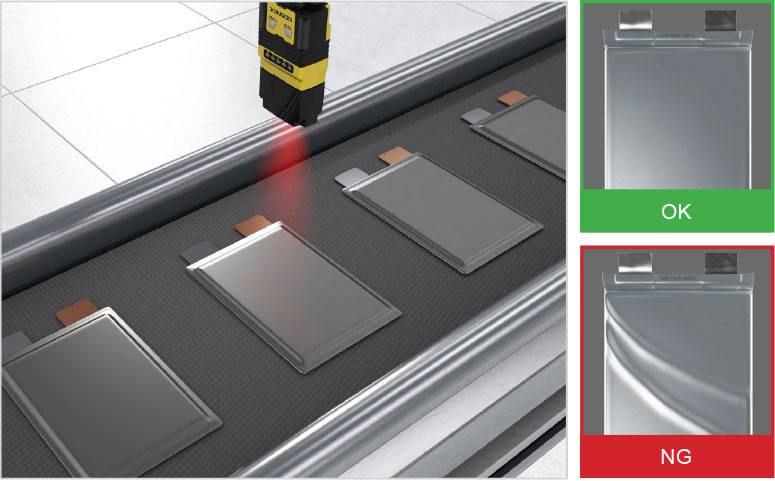

Electric Vehicles

Identify surface-level defects, such as scratches, dents and tears

2-Class Classifier

Automotive

Verify product completeness

Consumer Packaged Goods

Inspect labels on final packaging

Electronics

Confirm presence/absence of components during product assembly

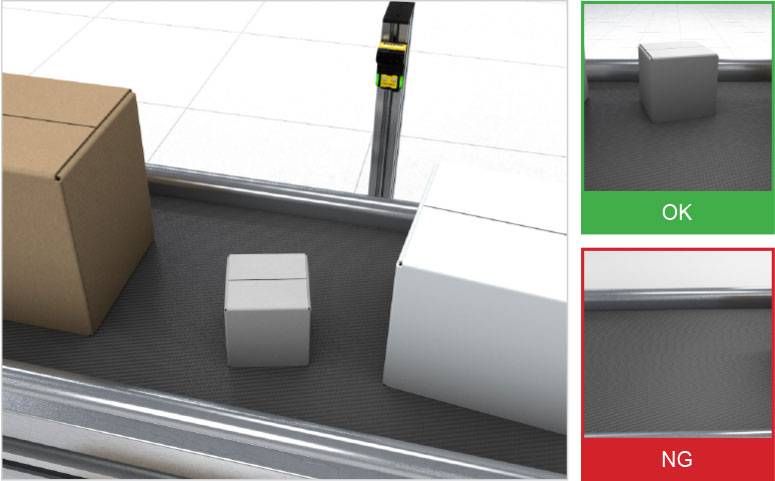

Logistics

Automate process control to ensure items come down the line in the right place at the right time

FEATURED COGNEX PRODUCTS

INTRODUCE

VISION SENSOR

IN-SIGHT VISION SYSTEM

IN-SIGHT 7000